202, Akshay Apartment, 473+475, J.M.Road, Shivaji Nagar , Pune 411005

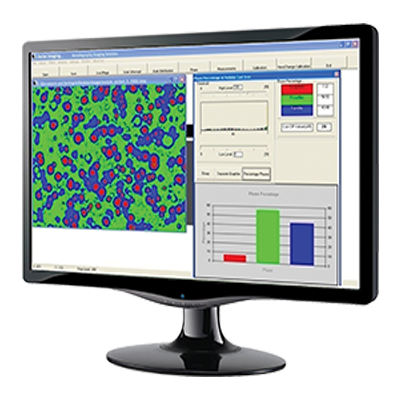

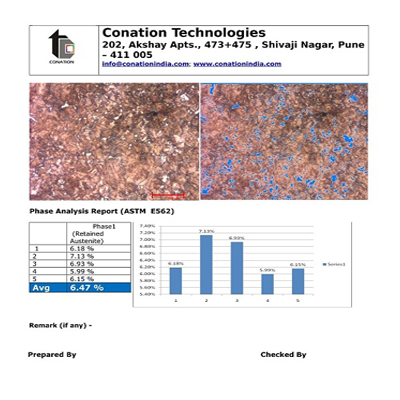

Dedicated Image analyzing systems for Metallography, Welding, Textile, Printing, Petrology, Clinker, life science etc. Specific needs, customization and up-gradation addressed through highly proficient development team Options available for hardware (camera and frame grabber) from proven international brands like Sony, JVC, Hitachi, Watec, Data Translation, Matrix Vision, Matrox etc

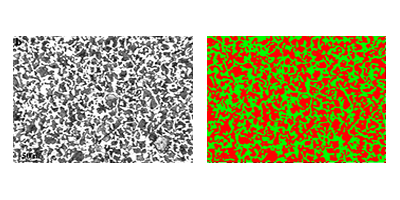

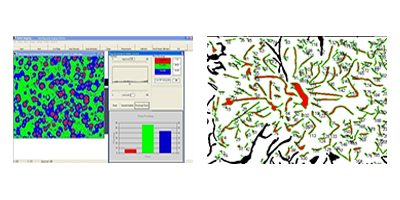

These analyses are used in various applications such as estimation of case hardening layer, decarb layer, interlamellar distance, particle count and size etc.

Computerized systems for Vickers, Microvickers, Brinell Hardness tester

Result display – serial number, test force, hardness value, length of diagonals, averages, standard deviation, minimum value, maximum value etc

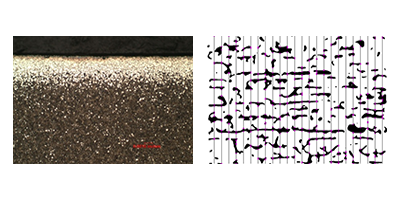

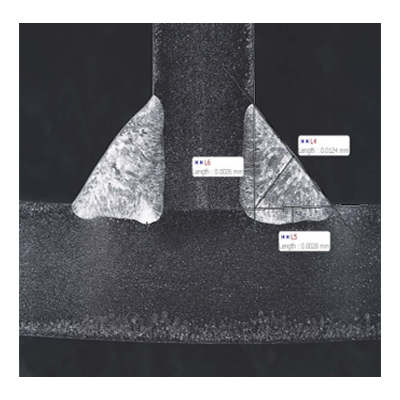

Dedicated Analyzer for weld penetration depth, bead width, leg length, HAZ and other weld parameters’ analysis

Flexible tolerance limit facility with GO/No GO indications for observed readings

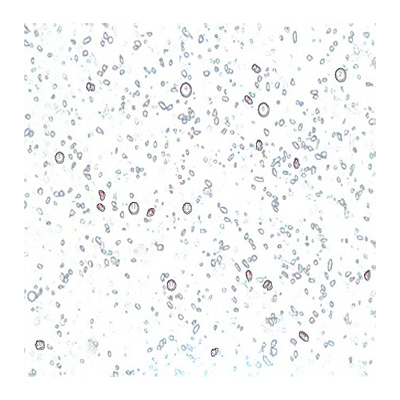

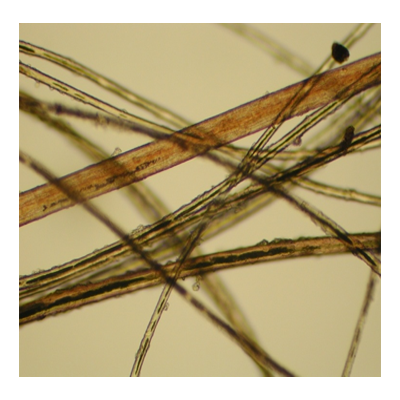

Fibre analysis like denier micron, diameter, convolution, fibre blends, med and kemp fibre content etc

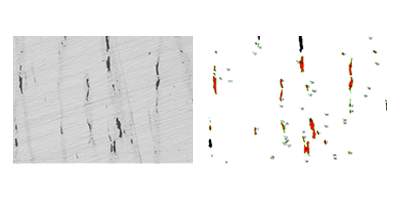

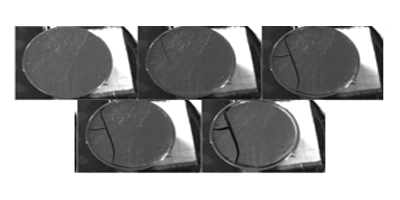

Customized software for capturing the images at desired time interval and analyze images for their parameters over the time

Eg. Crack generation and propagation with time in cement block

Printing defect analysis such voids’ measurement, missing print area, missing dot count, unprinted area in solids and half tone etc

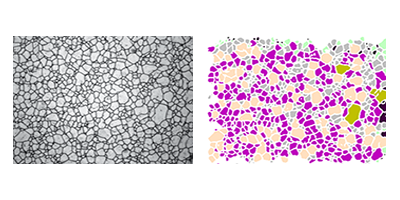

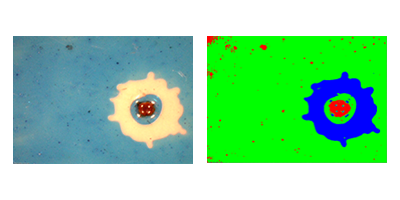

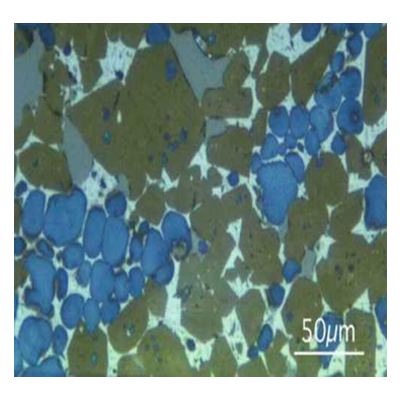

Dedicated system for counting various phases like Alite, belite, aluminate, ferrite, voids etc

Leaf area, perimeter, length etc, automated measurement for healthy and pest damaged / diseased area, root length, number of branches, tips and overlaps etc

202, Akshay Apartment, 473+475, J.M.Road, Shivaji Nagar , Pune 411005

info@conationindia.com

+91 (020) 25530244

+91 9405005555

+91 9405000222

Working : Monday-Saturday, 9AM-6PM

Weekly Off: Sunday